Experienced Boat Builders

“MJMs are built like the Boeing Dreamliner. They could last 100 years!”

- Soundings Magazine

What makes an MJM different?

It all starts with the vision and the design. A stronger, stiffer, and lighter high-tech construction with a low vertical center of gravity (VCG) sets MJM Yachts apart from others in the marine industry

Typically, powerboat builders build boats that are heavy and cheap, then add more horsepower. This left the door wide open to create MJM Yachts to build a motoryacht with strong/light high-tech epoxy composite construction. The net result was a faster, lighter motoryacht that delivered impressive fuel efficiency. “Twice the Fun, Half the Fuel” became MJM’s initial mantra.

When setting out to build the world’s most capable motoryacht, the vision was clear and ambitious. These yachts would not only need to be fast and fuel-efficient, but they also had to be far more comfortable and stable, and a step beyond anything available on the market. This means advanced design and engineering, an innovative manufacturing process, and tougher, more expensive materials. This quality of construction is one of the fundamentals that differentiates MJM Yachts as the finest in its class. The result is a hybrid that blends Downeast style with legendary North Carolina build quality.

What Is Advanced Design

With the concept and vision defined, the next challenge was design. Who had the best eye in the business for drawing a pretty boat? Using the latest computer-aided design (CAD) software, the design began to take shape. Just like designing a modern aircraft, there were many must haves. These included superior strength, exceptional sea handling capability, smoothness of ride and overall comfort, the best materials, and processes, and of course, she had to exude an uncommon beauty that would captivate mariners every time you entered a harbor.

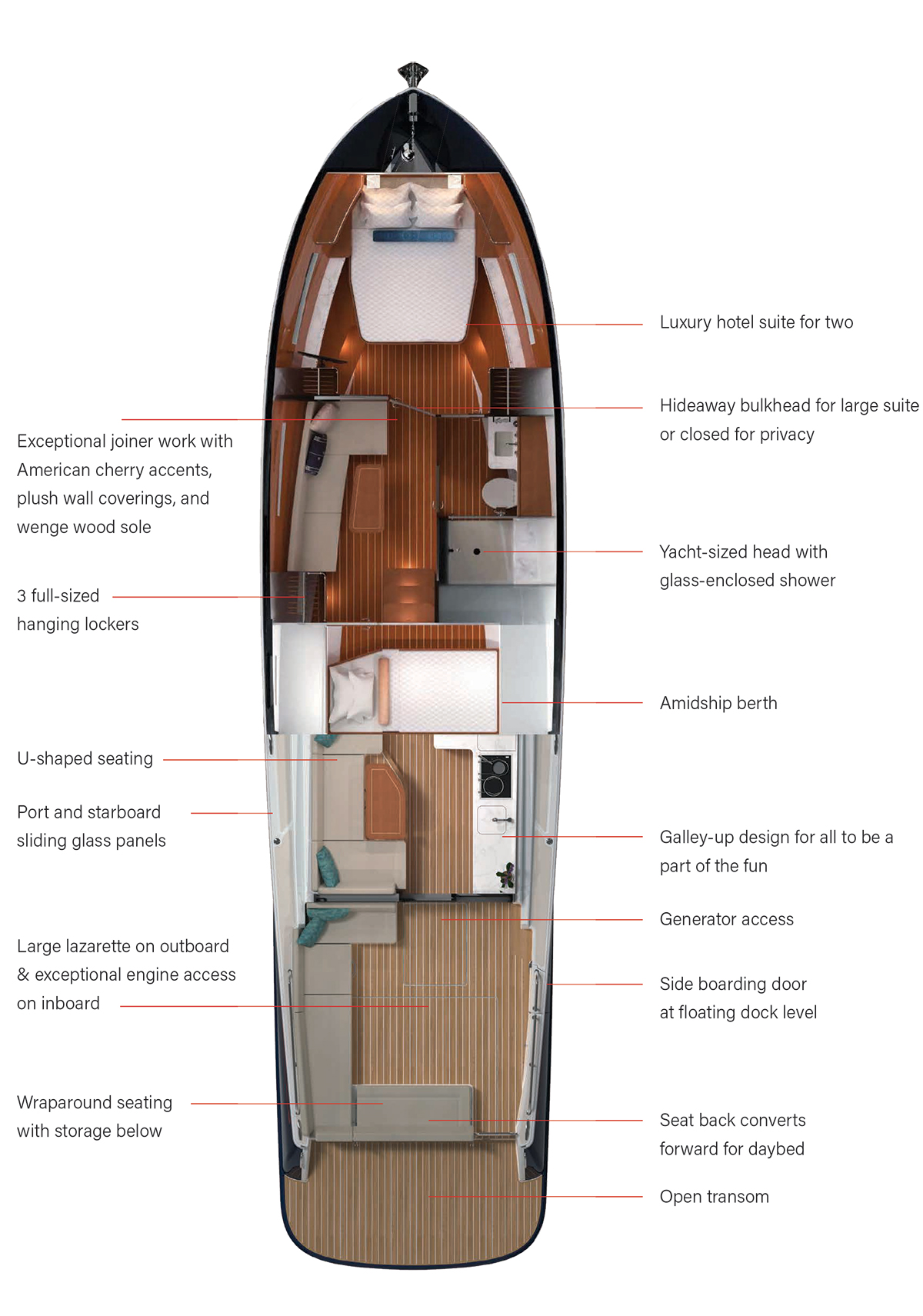

Integral to the overall design was the onboard experience, how does the space interact with people, the flow, and ergonomics. Unique to an MJM is the innovative flush deck design. This eliminates steps and provide a single level from the transom to the helm.

Next were side boarding doors at floating dock level, making boarding safe and easy in any situation. The next most noticeable feature is the protection of the pilothouse, but taking it to the next level is the fact that you can open it up to 360 degree access to your surroundings.

What's Innovative About The Layout?

- Indoor-outdoor flexibility

- 360 degree visibility

- Flush deck layout

Advanced Engineering

Computations for weight, vertical center of gravity and hull geometry all interact to determine the materials to be used to deal with the forces needing to be dealt with. The combination of design, engineering, materials, and processes determine the outcome, and is why an MJM is so stable, fast, and fuel-efficient. A key part of the design is MJM’s improved deep-V hull shape, which influences speed, stability, and handling. Other factors include buoyancy and bow shape, which on an MJM serves to eliminate a delayed response to the wheel, bow steer, or burying the bow in large following seas.

Not to mention helping to keep guests dry. A low center of gravity and narrow beam with chine flats redirect wave and wake energy outward and downward to dampen roll in a seaway. The deep-V entry hull shape slices through waves instead of slamming, pounding, or having each small wave create a mini collision and jolting the crew. This eliminates the fatigue experienced when driving other yachts.

Superior Materials

Each MJM yacht is constructed from superior materials selected specifically for weight, strength, stress loads, and function. Minimizing weight is essential in a performance yacht, but you can’t do that without increasing strength and stiffness.

Epoxy, though far more expensive than traditional polyester and vinylester resins, is a much better adhesive that is 25% stronger and has greater flexural strength for longer life.

Another advantage is the more tightly linked molecular structure that makes it almost impervious to osmotic blistering. In fact, the prescribed cure for boats suffering from bottom-blistering is the application of a new outer layer with epoxy resin.

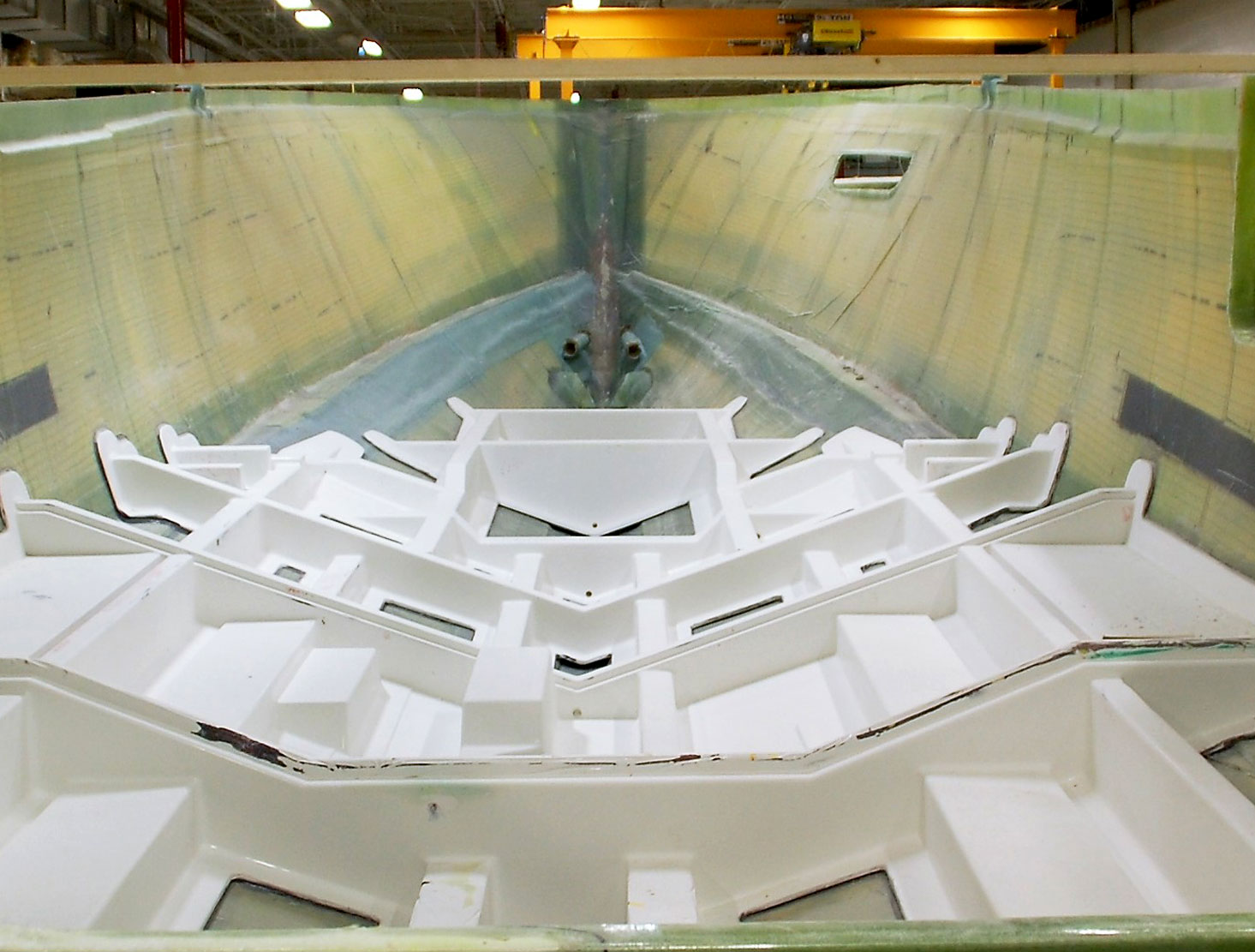

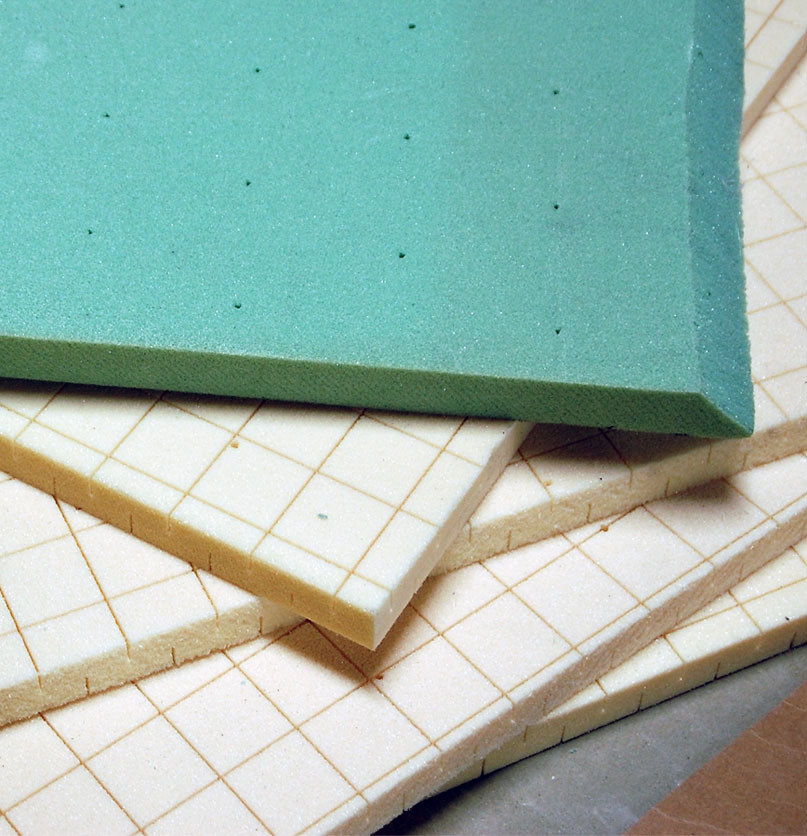

The combination of the Corecell and E-glass in the outer skin creates a structure like a continuous I-beam that is stiff, strong, and light. The engineering dictates what density of coring should be placed in various areas of the hull and deck. Each panel is pre-cut and numbered for installation.

Other builders use either the traditionally cheap method of laying sheets of cloth in the mold, spraying copious amounts of resin on it, then hand-rolling; or laying dry glass sheets in the hull, bagging it, then infusing a diluted resin by vacuum.

The process on MJMs results in a stronger 60:40 glass-to-resin ratio, rather than the reverse. Resin is glue and should be minimized.

“When it comes to the lifespan of today’s best-built boats…What’s to fail on an MJM? It’s an oven, post-cured epoxy boat. It’s as well-built as a Dreamliner, as far as I can see. There’s no reason that a boat like that couldn’t be here in 100 years.”

Eric Sorensen, Soundings Technical Editor

Advanced Composite Construction

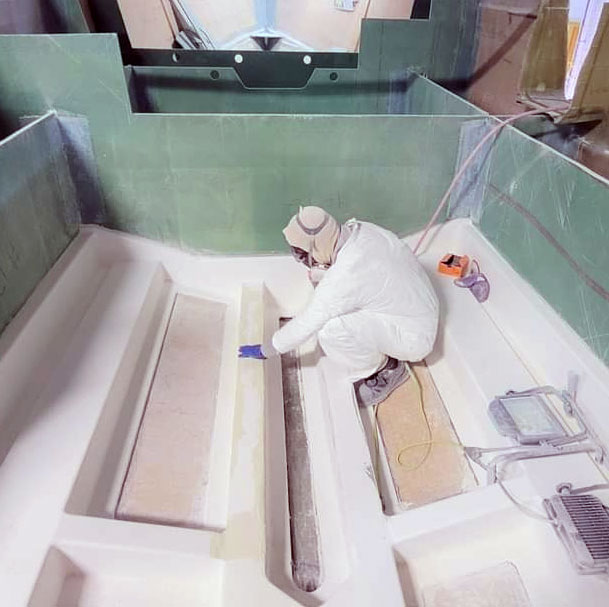

These materials are then utilized in a revolutionary process in the hull and deck molds. The inside of the mold is coated with a premium epoxy-compatible gelcoat. Then the outer skin is a E-Glass cloth. Next comes the waterproof Corecell structural foam, and finally the inner skin of E-Glass. Once the laminate is built ‘dry’, a vacuum bag is applied to the laminate stack, which compresses the laminate with a force of approximately 2,000 pounds per square foot. This process ensures there are no air voids and ensures a unitized, lightweight, and strong structure. All air is vacuumed out beneath the bag so that the weight of atmosphere is compressing the layers of composites. The vacuum also pulls out all moisture.

Once the vacuum is complete, resin is vacuumed through the part. Vacuum ensures the minimal amount of resin, and thus weight. When you examine MJM’s laminates under a microscope, the resin wraps around each bead detail on the foam surface, providing a mechanical bond, in addition to the superior adhesive bond of epoxy. The MJM infusion process leads to 25% better mechanical properties of a laminate versus other wet layup processes.

There is no wood in the structure of an MJM. The hull grid with foam-cored stringers and bulkhead landings are then installed and encapsulated in a fiberglass laminate. MJM applies the infusion process to all of its moldings, not just the hull or deck.

The last step in the lamination process is to post-cure the molded parts for 24 hours. This process allows epoxy to cure at a better molecular level than polyester and vinylester resins which on other boats continue to cure over the first year with the potential for serious print-through. Each hull and deck are post-cured for 16 hours at 140 degrees F.

Epoxy-built MJMs are stronger, lighter, and longer-lasting. With hull and deck structures comprising up to 25% of a boat’s total weight, you can understand why MJMs are in most cases many thousands of pounds lighter than similar-sized boats. But it doesn’t end there. Greater hull and deck weight requires more horsepower to reach acceptable cruising speeds. This means larger, heavier engines to get the boat going. Larger engines burn more fuel. That means bigger fuel tanks for reasonable range. It’s a vicious cycle. MJM has taken an industry leadership role to end that cycle and become “The World Leader in Fuel-Efficient Powerboats”.

Owner benefits are huge: better response at the wheel and more fun to drive; more speed per horsepower applied and a chance to take advantage of weather windows; and a lower center of gravity for more comfortable motion at sea.

back

x

Register for The MJM Experience Event

Join us at Persimmons Restaurant in New Bern, NC and discover what’s new for 2026.

"*" indicates required fields

"*" indicates required fields

I would like a dealer to contact me

2026 MJM 47R

38x-gallery-img-1

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

2026 MJM 47X

38x-gallery-img-1

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

2026 MJM 38RS

38x-gallery-img-1

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

2026 MJM 38R

38x-gallery-img-1

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

2026 MJM 38X

38x-gallery-img-1

38x-gallery-img-2

STAY IN THE KNOW

Join The MJM Newsletter Community. Get the latest information on MJM Yachts including new models, events, and more.

Pamlico Yachtworks

Department: Accounting

Position: CFO

Pamlico Yachtworks seeks CFO well-versed in all aspects of financial management ranging from simple accounting to broad investment and banking operations.

Key attributes for candidates:

- High-plant-touch orientation

- High technical financial, accounting and tax expertise, along with

- Exceptional “affability/teaming” attributes, in

- Complex, mid-tier manufacturing environments

Employee Duties & Responsibilities

- monthly/periodic financial reports and analyses.

- projections and budgets

- reconciliation with requisite supporting information for accurate presentation of the financial reports.

- Oversees the accounting function (accounting, accounts payable and payroll) and billing and collections functions of the organization.

- forecasting cash flows and operating results

- presenting financial and other information to the leadership team and the Board of Directors.

Requirements and skills

- Proven experience as CFO, finance officer or relevant role

- In depth knowledge of corporate financial law and risk management practices

- Excellent knowledge of data analysis and forecasting methods

- Proficient in the use of MS Office, MS Excel, QuickBooks, ERP and financial management software

- CPA is a strong advantage

- BSc/BA in Accounting, Finance or relevant field; MSc/MBA is a plus

Join the MJM Yachts Community!

Stay in the know. Get the latest information on MJM Yachts including new models, events, & more.

By submitting this form, you are consenting to receive marketing emails from: MJM Yachts. You can revoke your consent to receive emails at any time by using the unsubscribe link, found at the bottom of every email.

A Zurn Design