Innovative

MJM’S MARKET-LEADING POST-CURED EPOXY-INFUSION COMPOSITES. SUPERIOR STRENGTH, LIGHTER WEIGHT, MORE FUEL EFFICIENT, MORE SPEED!

Our composites enable a quieter ride, a safer lower center of gravity, and a more solid feel.

Individual

Design And Spec Your New Mjm

Choose your colors, power, and options, then download a rendering with pricing.

Designed By Boaters For Boaters

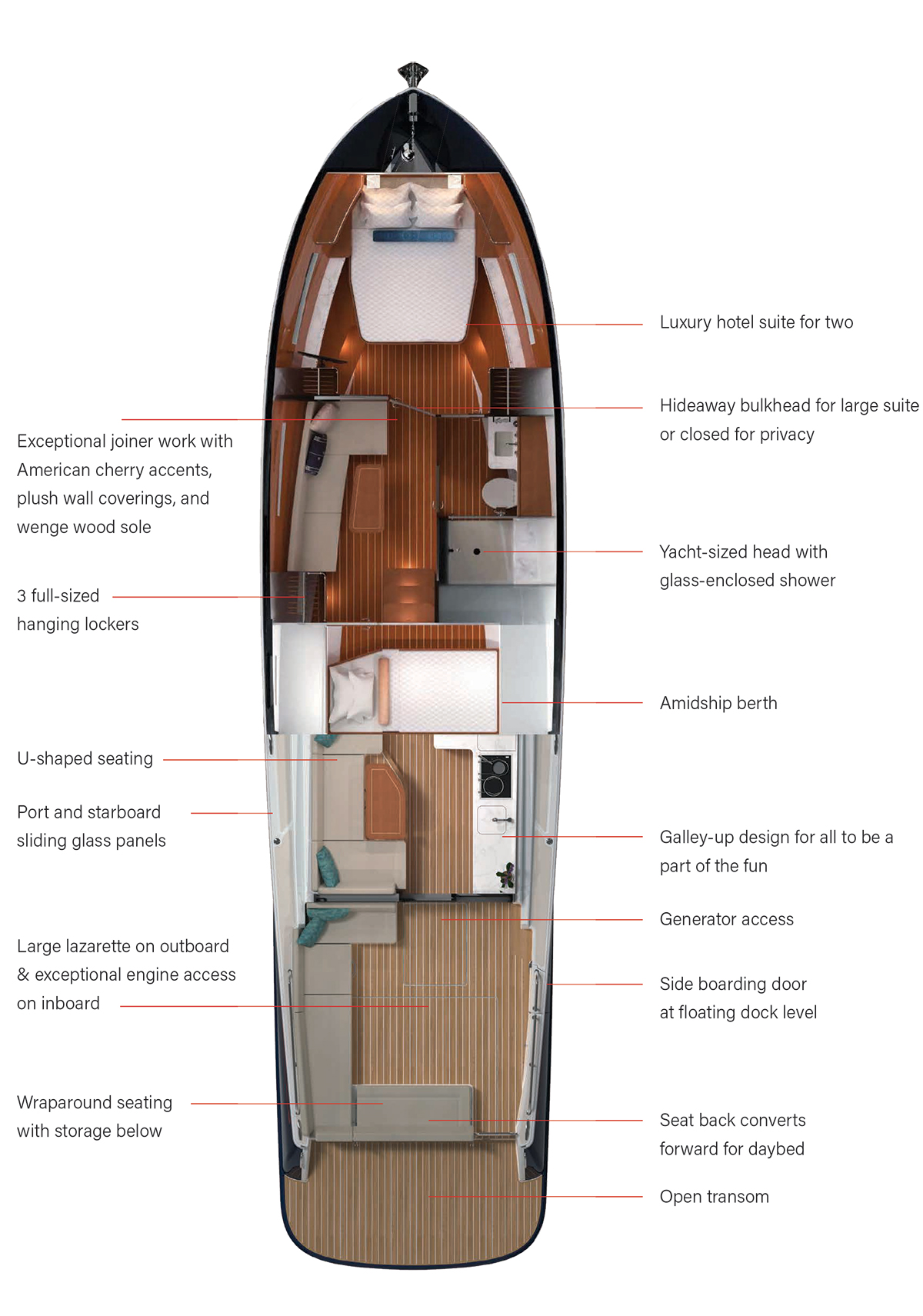

Seolta Holdings, the proud builder of MJM, designs and builds outboard & inboard luxury performance yachts in our own Carolina Downeast style.

In addition to being world renowned for stunning beauty, exceptional stability, smoothness of ride, high-tech construction, efficiency, and liveaboard comfort, our unique indoor/outdoor pilothouse provides 360° views, the enjoyment of fresh air with opening windshields, sides, and back, or full protection from the elements, extending your boating season and cruising comfort.

Articles & Reviews

Explore Now

Stay In The Know

Join The MJM Newsletter Community. Get the latest information on MJM Yachts including new models, events, and more.

Stay Form

A Zurn Design