MJM’s technology differentiator vs the market

MJM’s Market-Leading C5® Composite Construction Process

= Clean, Closed, Compressed, Cured, Composite.

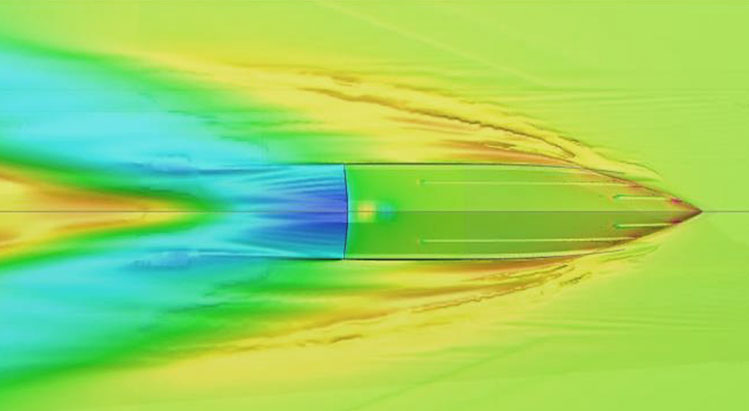

An MJM is so efficient that it can plane at 12 knots

MJM Yachts' high-tech structural composites lead the industry. High-strength lightweight composites allow a narrower and higher-performance waterplane. Check out the the plant tour from The Boat Show as they review MJM Yachts' class-leading construction C5 Build Process and why MJM yachts are Crafted for Life.

As you accelerate, the bow never rises. An MJM rises on its deep V for smooth and level acceleration. The fore and aft trim is always level, so the progressive deep V works correctly through a seaway.

The bow of a heavier boat rises when trying to accelerate on a plane and needs to reach 20-24 knots before planning occurs, and then bow can come back down. Heavier boats have difficulty running between 10-24 knots. Their bows are up, and their bellies are exposed to pounding waves.

An MJM rides comfortably and nimbly through this speed range, which is critical in rough conditions.

Half The Weight,

Twice the strength

When the composites were studied under a microscope, our former process showed the E-glass adhered to the tops of each bead of the foam core surface. The C5® process enveloped each foam core bead completely and bonded to the entire foam core surface, forming adhesive and mechanical bonds between the E-glass skins and the structural foam core. MJM’s C5® Process is a leap in technology vs the earlier wet-preg process. Compared to typical production powerboats, MJM’s C5® process typically delivers half the weight and twice the strength.

To innovate, improve, and lead, MJM set up its dedicated high-tech composites factory to apply the latest clean and closed aerospace composite techniques. MJM enlisted some of the brightest minds to develop a new process to lead the yacht market in lightweight, high-strength composites.

A five-year multi-million-dollar investment in development yielded our next-generation composite process.

Innovation & Continuous Improvement

Given the same composite materials, independent testing confirmed that MJM’s C5® process led to 25% more strength and 15% less weight over more traditional materials and processes.

MJM’s C5® Process is applied to our hulls, structural grids, decks, arches, lids, and pilothouse roofs.

The C5 Process delivers:

Lower Center Of Gravity

More stability, less motion, and greater safety.

Lighter Weight

- A narrower water plane for less motion through a seaway

- Level acceleration and no bow rise

- Planing begins at 12 knots. In the roughest seas, choose your comfort able speed, always with a level ride

- Superior speed and fuel economy from less horsepower

Greater Strength

- A quieter, tighter, and more solid feel is reassuring in a rough seaway

- Heirloom quality construction to pass down through generations

- Enhanced impact resistance

- Engineered to withstand the elements

What is MJM’s C5® Process?

C5® = Closed Compressed Clean Oven-Cured Composite. MJM’s C5® Process is an aerospace composite technique applied to yachting.

A description of our process:

DRY STACKING COMPOSITES

Precision table-cut E-glass and CNC-cut structural foam composite layers are dry-stacked in the mold without epoxy. E-glass overlaps and fiber orientation are positioned strictly for engineered performance. The structural foam is tightly fit and free of gaps.

HIGH-TECH MEMBRANE

A high-tech membrane covers the dry stack to allow air and gases out and resin in. After the epoxy hardens, it is removed.

CLOSED PROCESS

An impervious sealing layer makes C5® a closed vacuum process devoid of air.

COMPRESSION OF THE DRY STACK

High-capacity pumps vacuum the air from the closed process to 20 millibars. The atmosphere is at 1000 millibars, so the dry stack of E-glass and foam core is compressed by 2000 lbs per square foot of atmosphere. The woven E-glass compresses to half its volume, reducing the epoxy volume by half.

EPOXY MIXING

Our custom-developed epoxy resin formulation is precisely mixed by machine for the vacuum infusion process.

CLOSED VACUUM EPOXY INFUSION

The epoxy is drawn into the compressed dry stack vacuum, combining the composite layers into one bonded structural unit, akin to an I-beam. No fumes, odors, or volatile organic compounds are emitted into the environment. The epoxy is contained within the closed vacuum process, which achieves a 30% resin to 70% E-glass ratio, on par with the highest-performance aerospace composite processes.

CONVECTION OVEN FOR POST CURING

The hull, structural grid, deck, and pilothouse roof are post-cured at 185F degrees for 8 hours in MJM’s custom-built high-tech 20’ x 60’ convection oven. Sixteen thermocouples measure and log the composite temperatures across the part to ensure an even post-curing cycle. Why is post-curing beneficial? The heat transforms the epoxy by cross-linking the polymers, leading to a 30% increase in part strength—just from cooking! No other production boat builder delivers the sophistication, data, and controls of MJM’s high-tech post-curing process. The custom convection oven and its computer controls are unprecedented.

The Luxury Of Comfort

Ride comfort is our goal. Regardless of sea conditions, MJMs can enjoy any day on the water with a smooth, soft ride. The MJM C5 Process provides a lower center of gravity for less motion. The narrower waterplane allows the hull to knife through seas. The spray chines redirect the water’s energy outward and downward to dampen roll in a seaway. An MJM does not endure the slamming and pounding that jolts families on wider, heavier yachts. The smoother ride minimizes fatigue, allowing a longer running day.

Efficient Performance

Delivering More with Less

Less weight, a narrower waterplane, and low-speed planing reduce the need for horsepower. An MJM delivers more fuel efficiency and speed with less horsepower. The key differentiator is our C5® Process, which is half the weight and twice the strength. High-tech composites make MJM a unique high-performance yacht. You can go further and stay out longer. Spend more time out there and less time at the fuel dock!

The Carolina-Downeast Design Vision

The MJM C5® Process makes key MJM differences possible: fast and fuel efficient, a solid and smooth ride, with comfort and safety in any condition. When you take the wheel of an MJM, you will instantly feel the difference. An MJM accelerates and handles like a sports car. Your family will enjoy the ride; you will enjoy the responsive handling.

Yeah, but can’t I buy a heavier boat for less money?

Yes, heavier, low-tech boats cost less money. The builders focus on minimal mold cycle time and rely on copious amounts of resin to wet out low-tech fiberglass materials. Remember that you must double the horsepower to drive a heavier boat at the same speed for the rest of that boat’s life. You will consume up to double the fuel every time you go boating. A heavier boat typically needs 20+ knots of speed to plane. The bow will rise until on a high-speed plane, making safe and comfortable operation between 10-20 knots challenging.

Why use Epoxy versus Polyester or Vinylester?

Epoxy is stronger and more elastic. It can stretch 6% before breaking. It is impervious to water, so an epoxy composite has no risk of moisture intrusion and osmotic blistering as polyester boats can endure. Polyester is a cheap resin that can only stretch 1%. Polyester fails before the stretch limit of fiberglass, which is why you see crazing on many volume production boats. Vinylester is between Epoxy and Polyester. Like Epoxy, it is impervious to water. Most boat manufacturers use a Vinylester skin behind the gelcoat to prevent osmotic blistering but then utilize cheaper polyester resins for the bulk of their lamination.

Why don’t more builders develop a vacuum infusion process?

Infusion begins with molds built to an infusion vacuum-drop specification. Typical production molds are too porous for the vacuum infusion process. Air seeps right through the mold surface, preventing an adequate vacuum. Infusion molds cost more and take longer to build. You cannot simply convert existing production tooling to an infusion process. Every mold must be built to the process. Most builders are wed to their outdated processes and defend them for a reason. The investment in all new tooling would be too high. It would take 10+ years to change over all models to infusion specification tooling.

Training an entire composite staff to perform the vacuum infusion process can take 12-18 months. Mastering the process for reliable production can take 4-5 years. Most established builders will choose to keep their inferior existing processes rather than invest. Remember, if it is an open and wet process, it is an old and inferior process.

Why not use Carbon Fiber?

Carbon can make sense when used as local reinforcing and highly loaded parts like arches. It is more suitable for widespread use in racing, where longevity is not a concern. Carbon costs more and delivers more noise and higher repair bills. Some of the downsides of carbon:

- The CE Skin Thickness Scantlings Make it Pointless to Use The composite skin scantlings within the CE building code for composites require minimum skin thicknesses for impact resistance, regardless of the material. E-glass skins deliver far more strength and rigidity than structural engineering requires. If you were building a disposable racing boat without the CE code skin thickness requirement, you could utilize thinner skins to save weight with carbon. In the recreational market, most top builders will conform to the CE code for skin thicknesses, or risk significant liability.

- Carbon Corrosion Issues A yacht uses hundreds of SS fasteners and component. Carbon and SS begin corroding on contact, risking the long-term integrity of SS fasteners and components. The saltwater environment speeds up the corrosion process.

- Carbon Electrical Grounding Issues Carbon is the most efficient conductor of electricity. A modern yacht is brimming with electrical luxuries. The fasteners can bridge the electrical equipment to the carbon structure, creating a ground current. The entire carbon structure can become electrically charged. Underwater metal is particularly vulnerable to such electrical grounding issues, leading to rapid pitting and deterioration. It is nearly impossible to troubleshoot and resolve an electrically charged carbon structure without removing every fastener and system aboard.

- Carbon Lightning Issues Vacuum infusion processes can successfully integrate carbon without air voids. Wet composite processes will have air voids despite builders' best efforts. Why are air voids such a risk? When lightning strikes a yacht, it takes the most conductive path. Carbon is the most conductive material available. Lightning will run through carbon, rapidly heating any resistance, such as air voids. The air instantly heats and expands, blowing apart composites around the expanded air void. A lightning strike blew out 100+ air voids in one wet laminate carbon racing sloop. The entire hull had to be rebuilt. Would you place your family at risk?

back

x

Register for The MJM Experience Event

Join us at Persimmons Restaurant in New Bern, NC and discover what’s new for 2026.

"*" indicates required fields

"*" indicates required fields

I would like a dealer to contact me

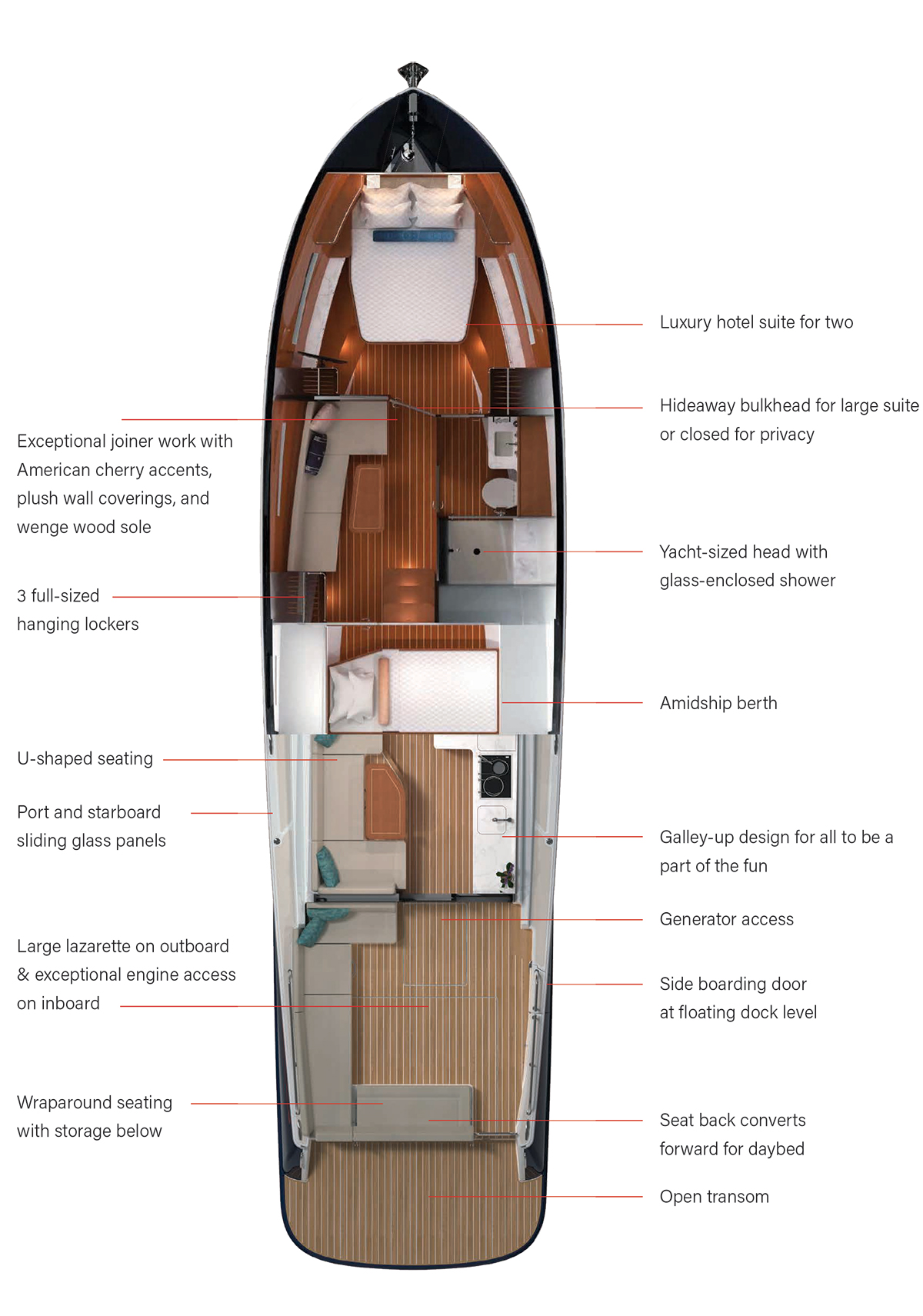

2026 MJM 47R

38x-gallery-img-1

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

2026 MJM 47X

38x-gallery-img-1

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

2026 MJM 38RS

38x-gallery-img-1

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

2026 MJM 38R

38x-gallery-img-1

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

38x-gallery-img-2

2026 MJM 38X

38x-gallery-img-1

38x-gallery-img-2

STAY IN THE KNOW

Join The MJM Newsletter Community. Get the latest information on MJM Yachts including new models, events, and more.

Pamlico Yachtworks

Department: Accounting

Position: CFO

Pamlico Yachtworks seeks CFO well-versed in all aspects of financial management ranging from simple accounting to broad investment and banking operations.

Key attributes for candidates:

- High-plant-touch orientation

- High technical financial, accounting and tax expertise, along with

- Exceptional “affability/teaming” attributes, in

- Complex, mid-tier manufacturing environments

Employee Duties & Responsibilities

- monthly/periodic financial reports and analyses.

- projections and budgets

- reconciliation with requisite supporting information for accurate presentation of the financial reports.

- Oversees the accounting function (accounting, accounts payable and payroll) and billing and collections functions of the organization.

- forecasting cash flows and operating results

- presenting financial and other information to the leadership team and the Board of Directors.

Requirements and skills

- Proven experience as CFO, finance officer or relevant role

- In depth knowledge of corporate financial law and risk management practices

- Excellent knowledge of data analysis and forecasting methods

- Proficient in the use of MS Office, MS Excel, QuickBooks, ERP and financial management software

- CPA is a strong advantage

- BSc/BA in Accounting, Finance or relevant field; MSc/MBA is a plus

Join the MJM Yachts Community!

Stay in the know. Get the latest information on MJM Yachts including new models, events, & more.

By submitting this form, you are consenting to receive marketing emails from: MJM Yachts. You can revoke your consent to receive emails at any time by using the unsubscribe link, found at the bottom of every email.

A Zurn Design