The Perfect Combination

By Kevin Koenig, Soundings Trade Only

MJM puts the Down in Down East with a new factory in North Carolina

In a lot of ways, it all started with dog food.

Before he became the legendary proprietor of J/Boats, and long before he founded MJM Yachts in 2002, Bob Johnstone toiled away in the marketing department at Quaker Oats, trying to figure out a better way to get more food down the collective gullet of a nation of hungry Fidos. The flavor he was selling was hamburger. And one day after noodling on the product, he came up with a way to improve it: As with most things in life, Johnstone figured it would be better combined with cheese. And thus was born the world’s first cheeseburger-flavored dog food. It would become a best-seller and propeled Johnstone’s career forward, becoming a small but seminal moment in the marketing genius’ long and storied life.

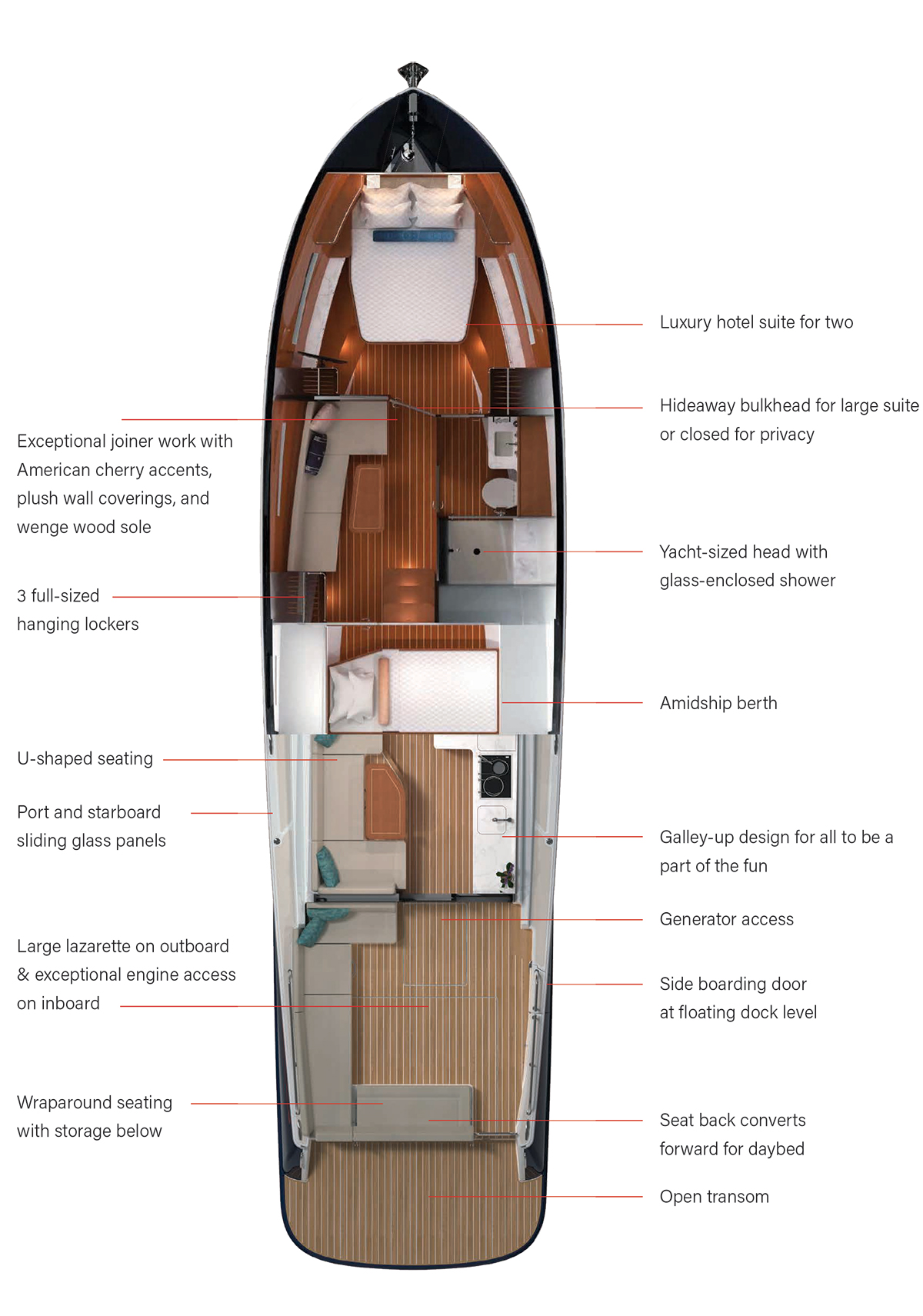

The new MJM 4 can be equipped with twin outboards to 600 hp each. Electrically controlled windows are a signature MJM design element.

It would turn out that winning combinations run in the Johnstone family. Bob’s son Peter Johnstone is currently at the helm of MJM Yachts, overseeing the transference of the bulk of its builds from Boston Boatworks, where it subcontracted, to a factory in Washington, N.C., about 50 miles west of Cape Hatteras and the Pamlico Sound. Despite New England origins, Down East-style boats are built the world over. So the change is not necessarily novel, but it is substantial, and it’s one that the younger Johnstone is excited about. Really, he sees nothing but upside.

“I chose North Carolina because the state has the right mix of low utility costs and overheads, and low facility costs,” says Johnstone. “The workforce is reasonably priced and knowledgeable. And North Carolina’s got a good productive labor attitude. It’s a productive area of the country. North Carolinians enjoy working hard. There’s a whole culture of it. There’s a reason why all the automobile and van manufacturers and plane makers are in the Southeast. It’s the right work ethic and productivity for the right price, and you clearly get great quality.”

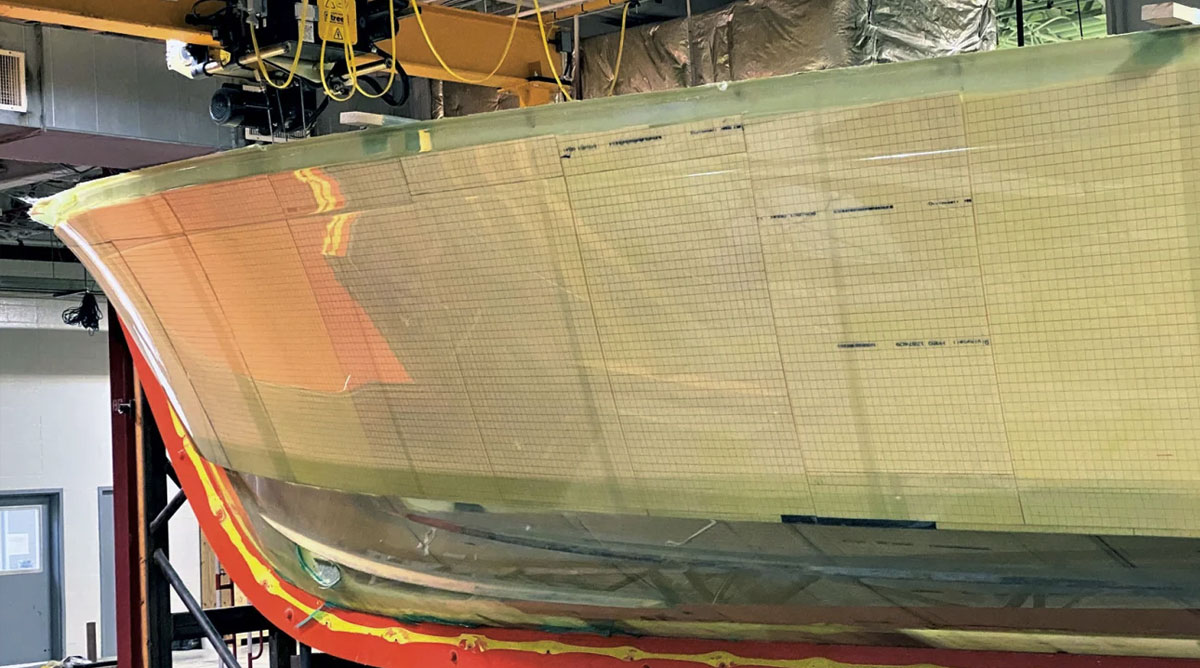

At MJM’s new facility in North Carolina, the builder will continue to utilize its proprietary vacuum infusion formula, with post-cured hulls, decks and pilothouses.

Of course, boatbuilding and seafaring history run rich and deep here. Hatteras, Grady-White, Regulator, Scout, and Fountain all build in North Carolina, to name a few, in addition to the litany of custom yards near Cape Hatteras.For Johnstone, joining the storied milieu was a no-brainer.

“The supply chain is set up here for production boatbuilding on a daily basis,” he says with more than a hint of pride. “Route 95 is close to us, and we are right on the water for direct delivery. Customers can drive their boats straight from the factory, and when they get out into the ocean, they have equal access to the great cruising regions of the Northeast and the South — there’s equal access. The central location of North Carolina is fantastic for the way that it opens up a boater’s options for cruising.”

Johnstone sees another big advantage to building in the Southeas, as opposed to the Northeast: the cost of living. “There’s a real blue-collar work ethic down here,” he says. “The workers are boaters and fishermen themselves, so they really understand the work they are doing in an intimate and expert way. And there’s a low cost of living near the factory, so the workers can actually live near where they work, which they couldn’t really do in Massachusetts. That goes a long way for quality of life and it manifests in the quality of work.”

As excited as he is for the Carolina move, though, there is a bittersweet aspect to the exodus from Boston. “We built everything at Boston Boatworks until last fall,” says Johnstone. “We had a really strong relationship with [co-founder] Mark Lindsay, but he died unexpectedly. He was the core of the business up there … the reason we were there. So the personal connection was gone, and also, they could only turn out about 25 to 30 boats a year, which was holding us back. So we set out for Carolina as fast as we could. And Mark’s death really sped the whole process up. We have 10 more boats to build in Boston, and then we are out.”

Though Johnstone had nothing but praise for Boston Boatworks, he is relieved to be beyond subcontractors. In the past, he’d run into major problems with Chinese subcontractors with Gunboat, so fully controlling his own destiny with MJM is not only a point of pride, but also a relief. “As we have grown, we have really felt the need to control our own production and maintain and exceed our own quality,” he says. “We’ll be able to really focus and do just that in Carolina because it’s our own thing. We can run six production lines. We have capacity for 100 to 200 boats per year. Anytime you set up operations it takes a good 18 to 36 months before you really feel like you have a new facility firing on all cylinders though, of course. We started in February [2021] and … it is going about as smooth as it can for a new operation. And the product coming out is just absolutely stunning.”

Back to that dog food. What the elder Johnstone accomplished with his cheeseburger product was to take an old stalwart and marry it successfully to something with flavor. In MJM’s context, that means blending traditional Down Easters with the chutzpah that has had fishing boats charging out of North Carolina’s Oregon Inlet for decades.

“We call it a Carolina Down Easter,” says Peter Johnstone. “It’s a mixture of offshore prowess with a flared bow and deep-vee hulls but combined with the classic [lines] of a boat from New England.”

MJM boats have proven to be fast and seaworthy — I recently ran the 53zi from Newport, R.I., to Boston doing 35 knots the whole way. The ride was remarkably smooth, and docking was a cinch, thanks to the boat’s feathery displacement; it’s easy to push and pull off pilings when your boat isn’t carting around extra baggage.

Not surprisingly, the hulls are of utmost importance to the Johnstones. The transom deadrise runs a third of the way up the boat,” Bob Johnstone says. “And then it transitions to a sharper 55 degrees forward. Our boats you could put on autopilot running down 6 to 8-foot seas and read a book.”

Like all MJM models, the bridge deck on the MJM 3 can be opened to the elements or fully enclosed.

It’s this seaworthiness that MJM believes makes the boats stand out from a crowded pack in the Down East niche. “We’re not building dayboats,” says Peter Johnstone. “Our customers really cruise; they really run their boats.”

So while the competition may style itself as the Champagne and caviar of the yachting world, they’d be wise to remember that there’s good reason everyone, be they human or canine, loves something with a bit more flavor and substance — like a really good cheeseburger.

MJM 3

The Perfect Combination - MJM puts the Down in Down East with a new factory in North Carolina In a lot of ways, it all started with dog food.… Read More

The Perfect Combination - MJM puts the Down in Down East with a new factory in North Carolina In a lot of ways, it all started with dog food.… Read More Tested: MJM 3 Dual Console - A new model, the MJM 3 Dual Console, and a new facility in North Carolina sparks the second act of MJM, and it’s off to… Read More

Tested: MJM 3 Dual Console - A new model, the MJM 3 Dual Console, and a new facility in North Carolina sparks the second act of MJM, and it’s off to… Read More Out for the Day - MJM HITS THE MARK WITH ITS NEW DAY YACHT THAT CAN CRUISE THE ICW AND TACKLE THE OCEAN. By Steve Davis | Southern Boating Boats… Read More

Out for the Day - MJM HITS THE MARK WITH ITS NEW DAY YACHT THAT CAN CRUISE THE ICW AND TACKLE THE OCEAN. By Steve Davis | Southern Boating Boats… Read More Line of Succession – Breakthrough Dual Console for Todays Boating Enjoyment - While knowing it would be making a splash with its new MJM 3 Outboard, MJM is instead creating a tidal wave of excitement in the… Read More

Line of Succession – Breakthrough Dual Console for Todays Boating Enjoyment - While knowing it would be making a splash with its new MJM 3 Outboard, MJM is instead creating a tidal wave of excitement in the… Read More MJM 3® – Spirited Seafarer - With a lineup of Down East-style express cruisers from 35 to 53 feet length overall in inboard and outboard confi gyrations, MJM Yachts is now… Read More

MJM 3® – Spirited Seafarer - With a lineup of Down East-style express cruisers from 35 to 53 feet length overall in inboard and outboard confi gyrations, MJM Yachts is now… Read More