How MJM Yachts Uses Advanced Composites to Build Luxury Yachts

Boat manufacturers have long leaned on composite construction materials due to their high strength ratio to lightweight structure, among other features. However, advancements in the manufacturing process have set the standard for an unprecedented quality of luxury yachts.

MJM Yachts integrates several advanced composites and procedures into our boat making process to provide each of our customers with the best yachts on the market. The DNA that comprises each of our yacht models is simple and consistent: we believe that every gram of weight should count for something. By using advanced composites, we ensure that each MJM is lightweight, durable, and high precision quality. Continue reading to discover exactly how MJM Yachts builds the best yachts year after year.

Making Every Inch Count

Every square inch of our luxury yachts plays its part in the overall performance. We believe that luxury yachts are only as strong as their weakest link, and our design process ensures that nothing will compromise the quality of an MJM. We marry a proprietary epoxy with a precision temperature controlled post curing process to produce our luxury yachts. We have engineered our laminate based on a quadriaxial hull reinforcement, which evenly distributes strength across all axes to prevent a single point from bearing too much stress.

Advantages in Weight, Strength, and Stiffness

We design and build all MJM Yachts to ISO standards. We achieve a precise ratio of 70% glass to 30% resin, and our process ensures that we achieve zero air voids. This means that no air ends up trapped in our laminate, which gives our high performance yachts an advantage in weight, strength, and stiffness. This also allows us to achieve an extremely low center of gravity which results in extreme stability.

Driving Design with the Best Equipment

Our sturdy boat designs wouldn’t be possible without driving the resin down as much as possible. Our vacuum compression process achieves 2,000 pounds per square foot, which results in precise compression of our composites. Rather than starting from scratch and using whatever equipment is laying around, we drive our manufacturing process with brand new equipment – including two post cure ovens, and up to 35 computer controlled thermocouples.

Incomparable Weight Reduction

By using vacuum infusion, epoxy, and structural fabric, MJM Yachts can reduce weight by up to 30%. This weight reduction is only possible with our unique design process. Otherwise, cutting that much weight may compromise the stiffness and strength of the boat. We do this by letting our epoxy systems rest in a mold for 24 hours until they are stable enough to unmold, then bake the hull, deck, and hardtop until the composites reach their target stiffness and strength.

Our precision composite process and use of superior materials is what makes an MJM world renowned for its performance, efficiency, ease of ownership, and overall fun.

MJM Founder’s New Book on Amazon - Time To Get Creative A page-turning business memoir and love story from this National Sailing Hall of Fame yachtsman, wrapped up in a narrative about… Read More

MJM Founder’s New Book on Amazon - Time To Get Creative A page-turning business memoir and love story from this National Sailing Hall of Fame yachtsman, wrapped up in a narrative about… Read More Yacht Company Sends New Employees Through BCCC Apprenticeship - WASHINGTON, N.C.— Large boat orders have picked up and manufacturing companies are frantically trying to keep up with the demand. Local yacht builder, Pamlico Yachtworks,… Read More

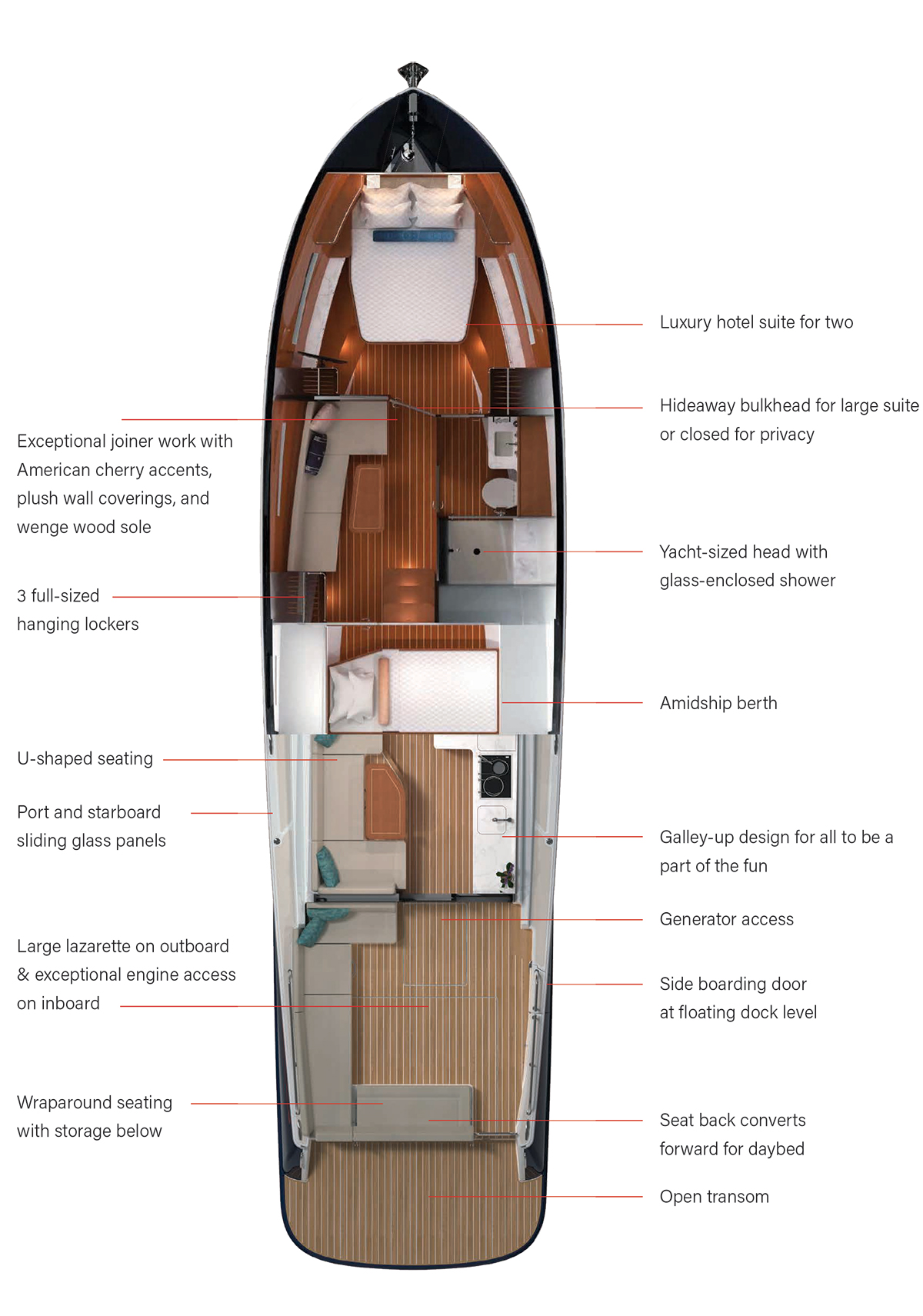

Yacht Company Sends New Employees Through BCCC Apprenticeship - WASHINGTON, N.C.— Large boat orders have picked up and manufacturing companies are frantically trying to keep up with the demand. Local yacht builder, Pamlico Yachtworks,… Read More Evolution Of A Dream - Designed and built to supply comfort, performance, and safety, the new MJM 42 is all that...and much more. The new MJM 42 is a luxury,… Read More

Evolution Of A Dream - Designed and built to supply comfort, performance, and safety, the new MJM 42 is all that...and much more. The new MJM 42 is a luxury,… Read More How MJM Yachts Uses Advanced Composites to Build Luxury Yachts - Boat manufacturers have long leaned on composite construction materials due to their high strength ratio to lightweight structure, among other features. However, advancements in the… Read More

How MJM Yachts Uses Advanced Composites to Build Luxury Yachts - Boat manufacturers have long leaned on composite construction materials due to their high strength ratio to lightweight structure, among other features. However, advancements in the… Read More The Perfect Combination - MJM puts the Down in Down East with a new factory in North Carolina In a lot of ways, it all started with dog food.… Read More

The Perfect Combination - MJM puts the Down in Down East with a new factory in North Carolina In a lot of ways, it all started with dog food.… Read More Design Driven - The MJM 53z is a Down East-inspired design, accented by stainless-steel bow rails that average around 30 inches high and mirror the form of the… Read More

Design Driven - The MJM 53z is a Down East-inspired design, accented by stainless-steel bow rails that average around 30 inches high and mirror the form of the… Read More How The MJM Yacht Design Makes For A Better Boating Experience - Learn about 2 of over 30 problems solved by the MJM Yachts design: Speed to outrun weather, and Overcoming rough sea conditions. Boating is fun,… Read More

How The MJM Yacht Design Makes For A Better Boating Experience - Learn about 2 of over 30 problems solved by the MJM Yachts design: Speed to outrun weather, and Overcoming rough sea conditions. Boating is fun,… Read More Three Strategies for Preventing the Corona Virus - You’re working remotely, monitoring the media reports-chances are you’re feeling the stress. Boating is a great escape. The stress-reducing power of fresh air, saltwater and… Read More

Three Strategies for Preventing the Corona Virus - You’re working remotely, monitoring the media reports-chances are you’re feeling the stress. Boating is a great escape. The stress-reducing power of fresh air, saltwater and… Read More