Designs on Greatness

By Dennis Caprio, Power and Motoryacht magazine

Photos by Billy Black

Modern construction, smart design, and practical engineering keep the new MJM 50z at the top of her game, and ready to make her owners very happy.

Commercially driven industrial design often breeds a certain level of ennui, because the results frequently look remarkably similar. We can’t blame the designers or the manufacturers. They merely have responded to the public’s whims and fancies, which can make or break any new product. The MJM 50z, on the other hand, has a distinctive personality, derived in equal measure from CEO Bob Johnstone’s knowledge of which features mean the most to the owners—ease of use, comfort, and pride of ownership—and Doug Zurn’s artful rendering of those features.

This adventure in marketing and manufacturing began 13 years ago. Johnstone wanted a motorboat that he and his wife Mary could enjoy together. It had to be light, handy, comfortable, and good-looking, but most important, easy for either one of them to handle solo. This boat would be Mary Johnstone’s motorboat, the 34z. That’s how the company got its name.

This adventure in marketing and manufacturing began 13 years ago. Johnstone wanted a motorboat that he and his wife Mary could enjoy together. It had to be light, handy, comfortable, and good-looking, but most important, easy for either one of them to handle solo. This boat would be Mary Johnstone’s motorboat, the 34z. That’s how the company got its name.

Johnstone’s insistence on easy handling, ease of use, and stimulating performance has kept his boats small. Years ago, I asked him if he planned to go longer than 34 feet. His answer was a qualified “maybe,” depending on the demands of the market. His product strategy, based on his experience with each model, has always been, What would I like? “If it doesn’t make sense to me,” he continued, “why would it make sense to anyone else?”

What Johnstone would like isn’t possible without carefully marrying high-tech construction with intelligent design. All of the ingredients have to interact perfectly. The pride of ownership that he hoped to elicit in the owners of MJM boats starts with “timeless good looks,” as Johnstone describes the 50z. Although each model of the line cuts a low profile, one of the most important ingredients in producing a handsome, relatively small boat, her length, gives the 50z the most pleasing proportions of the lot. The remarkably subtle rise and fall of her sheerline alone is enough to make the public swoon. Her open bridgedeck, sheltered as necessary by roll-down Isinglass panels, gives the after half of the boat a lacy appearance. Johnstone refers to this area as a flying bridge without the ladder.

Boston BoatWorks brings highly skilled craftmanship to the table.

At this year’s winter and spring boat shows, prospective buyers looking at a model of the 50z asked Johnstone if she’ll be available with a flying bridge. His answer was always, “No.” A flying bridge would ruin the profile and add weight high in the structure—exactly where it shouldn’t be when one of the builder’s goals is lateral stability. A tall superstructure also creates the additional windage that affects directional stability at planing speeds, as well as during low-speed maneuvering.

Boston BoatWorks builds all of the MJM models, and uses pre-preg Kevlar and E-glass fabric over a Corecell closed-cell foam core. Pre-preg is shorthand for fabric that’s impregnated with epoxy resin during manufacturing. This thermoset resin cures at a high temperature, and the chemical reaction transforms the laminate into a very durable, temperature-resistant, exceptionally stiff, and extremely lightweight structure. Vacuum-bagged pre-preg laminates avoid inconsistencies in the resin-to-fabric ratio, which creates a stronger and lighter boat, and pre-pregs reduce to a bare minimum the emission of dangerous volatile organic compounds (VOCs). Think green.

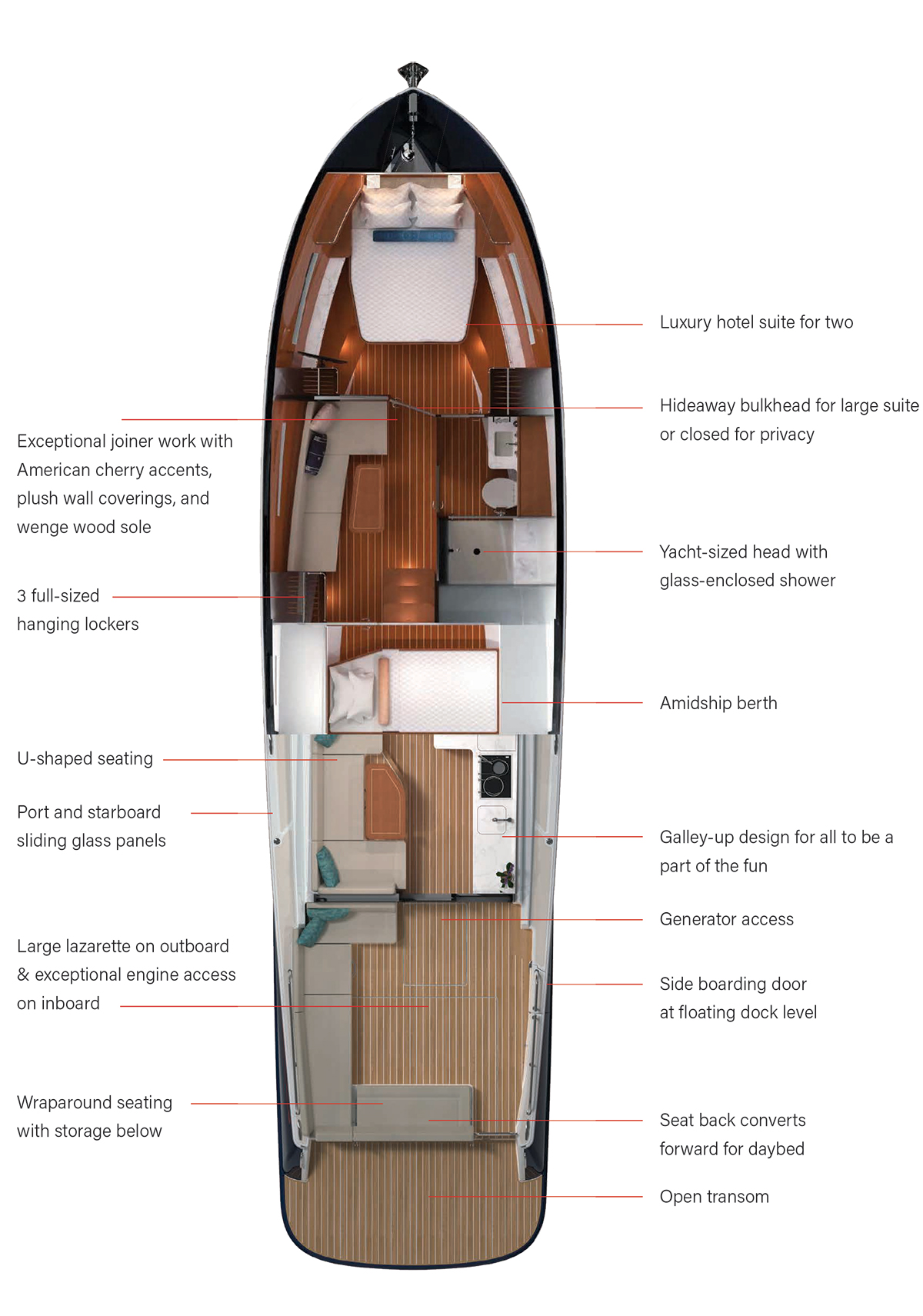

An open layout on he accommodations level will allow passengers to socialize while fully protected from the elements.

Many years ago, the only way boatbuilders could be sure that their laminates were strong enough was to over-engineer them. As a result, the boats were heavy, and weight is the enemy of performance and fuel economy. Nowadays, sophisticated computer-aided engineering helps builders escape this problem. MJM Yachts gets its engineering expertise from Burke Design. Owner Steve Burke works closely with Boston BoatWorks and Zurn Yacht Design, analyzing the kevlar/e-glass composite laminates and structure to ensure that they comply with the new ISO (International Organization for Standardization) small-craft structural requirements. He also coordinates the effort to obtain CE mark certification for the boat and its systems for marketability worldwide. The MJM 40z and the 50z are the only boats of their type to have an ISO rating of A Ocean, the international standard’s toughest design category. It’s defined as the “category of boats considered suitable for seas of up to 7 meters (23 feet) significant wave height and winds of Beaufort Force 9 (41-47 knots) or less.”

“The principal core material employed in the construction of the MJM is Corecell foam,” Burke writes. “Varying densities of Corecell are used in the hull and bulkheads of the boat. Slightly higher density foam is used in the hull bottom, due to the impact pressure of the waves at speed, while lower-density foam is found in the topsides and bulkheads. The advantages of Corecell are: First, the closed-cell foam core is impervious to water in areas damaged by collision. And second, Corecell foam is more tolerant than other core materials of large impacts, resulting in smaller areas of damage and potential delamination following a collision.

Making sure the MJM 50z’s hull is just right – it’s always a little jarring to see a boat in this stage of the game, isn’t it?

“Superlite Baltek Core material is used in the decks,” continues Burke, “for its higher compression strength against localized impact, so it resists small denting events, like dropping the bottom fin of an outboard engine or an anchor on the cockpit sole, better than the foam core used in the hull and bulkheads.” For extra protection against grounding or the sudden juxtaposition with a hard floating object, and in keeping with ISO standards, the MJM 50z has a solid fiberglass keel.

Building with pre-pregs lets the lamination shop keep an accurate record of how much the materials weigh; therefore, each example of a given model displaces the same amount. A fully loaded MJM 50z displaces 35,000 pounds, whereas other boats in this category displace up to 50,000 pounds.

Lightweight construction reduces the boat’s drag, letting the builder get the performance it wants with smaller engines. Smaller engines mean a further reduction in weight, giving the boat an even better power-to-weight ratio. Projections for the 50z indicate that she’ll burn 28 gallons per hour at a cruising speed of 25 knots.

Keeping top-hamper weight to a minimum lets the builder lower the boat’s center of gravity. This choice enhances lateral stability. Johnstone learned during his informal research on the docks and at boat shows that roll is among the most hated motions aboard any boat. That sent him on a mission to find out as much as he could about the Seakeeper gyro stabilizer. He learned that about 1,500 of these units are currently in service worldwide, most aboard large custom motoryachts. Then he drove a 30-something Intrepid equipped with a Seakeeper and could scarcely believe how stable she was. That’s when he decided to make the gyro stabilizer standard equipment on the 50z.

If this rendering proves accurate it’s safe to say MJM understands Down East proportions.

This decision unearthed a caveat. A 1,000-pound gyro spinning at 9000 rpm stresses the hull of a powerboat in much the same way a tall sailing rig and deep keel stress a sailboat’s structure. Once again, careful engineering and construction were called upon, this time to produce the strength to deal with the loads. The gyro sits on a structural grid.

The MJM 50z is very technically interesting, but more than this, her technology raises the owner’s level of enjoyment. The absence of wood on the exterior will reduce cleanup time at the end of a cruise and eliminates the expense of varnishing. Her light weight will make her accelerate and handle like a sports car, and at the same time, Zurn’s hull design (with an 18.5-degree transom deadrise) should give her a very seakindly ride. Aren’t these the reasons most of us love to drive powerboats in the first place?

Johnstone expects hull No. 1 to launch this August. Look for the 50z at the Newport International Boat Show this September.

MJM 50z Accommodations Versatility - Exploring the versatility of the second master suite and third cabin on the MJM Yachts 50z. Click Here to Watch the Video | Video Length… Read More

MJM 50z Accommodations Versatility - Exploring the versatility of the second master suite and third cabin on the MJM Yachts 50z. Click Here to Watch the Video | Video Length… Read More Timeless: The MJM 50z - MJM's 50z has classic lines, a high-tech build and a legendary builder pedigree. By Chris Caswell The MJM 50z is a thought-provoking yacht with some… Read More

Timeless: The MJM 50z - MJM's 50z has classic lines, a high-tech build and a legendary builder pedigree. By Chris Caswell The MJM 50z is a thought-provoking yacht with some… Read More Designs on Greatness - By Dennis Caprio, Power and Motoryacht magazine Photos by Billy Black Modern construction, smart design, and practical engineering keep the new MJM 50z at the… Read More

Designs on Greatness - By Dennis Caprio, Power and Motoryacht magazine Photos by Billy Black Modern construction, smart design, and practical engineering keep the new MJM 50z at the… Read More MJM Yachts Innovation in Layout, Entertaining and Design is Unsurpassed - Creating an open flow, spacious entertaining areas, and liveaboard comfort meant pushing conventional layouts aside. The MJM Yachts concept is to address the way owners… Read More

MJM Yachts Innovation in Layout, Entertaining and Design is Unsurpassed - Creating an open flow, spacious entertaining areas, and liveaboard comfort meant pushing conventional layouts aside. The MJM Yachts concept is to address the way owners… Read More MJM Yachts Advanced Manufacturing and Materials - To improve sailboat performance with the wind as a finite source of energy, Bob Johnstone knew that stronger, stiffer, and lighter high-tech construction with a… Read More

MJM Yachts Advanced Manufacturing and Materials - To improve sailboat performance with the wind as a finite source of energy, Bob Johnstone knew that stronger, stiffer, and lighter high-tech construction with a… Read More Category A “Ocean” Certification – What Does It Mean? - MJM made it a primary objective that all MJMs would be certified at the highest level of safety possible... which meant those models under 40… Read More

Category A “Ocean” Certification – What Does It Mean? - MJM made it a primary objective that all MJMs would be certified at the highest level of safety possible... which meant those models under 40… Read More Spring Cruise of 50z “ZING” - Our antidote for Winter has been a pair of 3-week cruises on our MJM 50z starting out in Naples FL, visiting Boca Grande, Sanibel, Sarasota,… Read More

Spring Cruise of 50z “ZING” - Our antidote for Winter has been a pair of 3-week cruises on our MJM 50z starting out in Naples FL, visiting Boca Grande, Sanibel, Sarasota,… Read More MJM Yachts 10th Annual Owners Luncheon Rendezvous - It was all fun, stories, and an afternoon of boating when more than 80 people attended the 10th Annual Owners Rendezvous Friday Luncheon at the… Read More

MJM Yachts 10th Annual Owners Luncheon Rendezvous - It was all fun, stories, and an afternoon of boating when more than 80 people attended the 10th Annual Owners Rendezvous Friday Luncheon at the… Read More Under Way With The 50z - Once you've cruised at 35 knots on a windless day to make passages like American Yacht Club in Rye down the East River, around Jersey… Read More

Under Way With The 50z - Once you've cruised at 35 knots on a windless day to make passages like American Yacht Club in Rye down the East River, around Jersey… Read More At The Dock With The 50z - When family and friends are aboard, you’ll love the plush seating and the sociable flush deck arrangements that allow your whole group to join the… Read More

At The Dock With The 50z - When family and friends are aboard, you’ll love the plush seating and the sociable flush deck arrangements that allow your whole group to join the… Read More